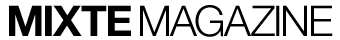

To transform a kitchen into a space that turns the everyday experience into the elevated, requires a unique designer. At PURE, surpassing the demands of luxury living is what we do best. One look at the scope of our portfolio and you’ll agree.

Smart advice, inspiring suggestions, proposals that get you fired up… it all comes from listening to your wants and needs. From the first conversations to the final results, we’ll stop at nothing to make your dreams a reality. Since everything starts with you, our goal is to guide you to where you want to go, offering you PURE support every step of the way.

From the word go, our designers will be transparent, engaged and passionate about delivering unparalleled results. The meticulous choice of manufacturers, our expertise in architectural integration, and our aesthetic/functional solutions are proof of this commitment. At PURE, it’s all about earning your trust.

Because we offer several high-end collections, your budget will ultimately determine every one of our recommendations. For example, any suggested finishes will always correspond with your taste and fit your finances. Detailed, step-by-step estimates will keep you up to date on the progress and variations in cost, if applicable.

At PURE, respect goes far beyond your vision and budget. We also have high regard for our innovative designers who are the backbone of our team and fully endorse our splendid European collections. And because we respect the parameters of your project, we only select the products that make sense for you and your life every day.

Always remember that major projects take time. Ex. It takes 6 to 8 weeks to manufacture a kitchen and 3 more weeks to deliver products from overseas. In short, from our first meeting to the delivery, plan a minimum of 4 months.

- Support by accredited designers

- A plan for design

- A plan for electricity

- Taking laser measurements

- Site visits

- Impeccable follow-up

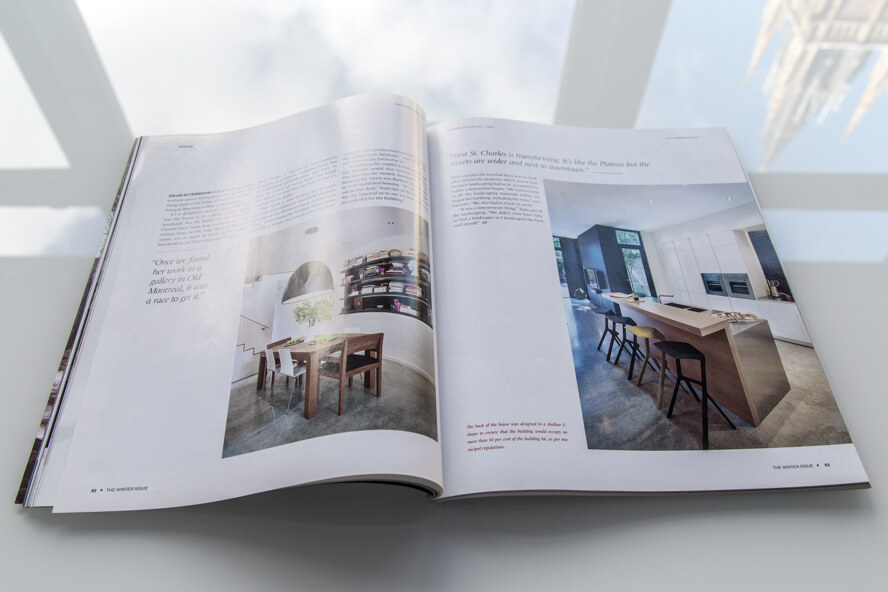

Made in Italy is the ultimate symbol of quality and prestige. These three words have come to represent authentic craftsmanship, timeless elegance, and impeccable style. The expertise of artisans handed down from generation to generation combined with modern day technological advances explain why Italy has remained at the forefront of design for centuries.

At PURE, our goal is to introduce you to the industry’s finest designers, materials, and textures. Think of us as your gateway to an exclusive world of unparalleled elegance.

Cesar furniture carcasses is made using V100 particle panels that have the highest level of water resistance for internal use. The panels we use in our furniture have very low formaldehyde emissions (Carb Phase II compliant/TSCA Title VI compliant). Cesar is FSC® certified, mark that guarantees the traceability of the wood used and that is comes from responsibly managed forests. Because we firmly believe that the condition of tomorrow’s world depends on the actions that we take today.

“Ask for FSC® certified products.”

INDUSTRIALISATION AND SUSTAINABILITY

In a research for a more sustainable raw material with respect to the environment and its resources, CEADESIGN has chosen as one of the first faucet producing companies stainless steel as its main raw material for its entire product range guaranteeing a 100% stainless steel production plant excluding any possible contamination with other metals. Stainless steel is universally recognised as an eco- friendly material that needs far lower temperatures to be produced in comparison to other metals. CEA adopts cold working methods for stainless steel using highly precise numerical control machines. No hot melt treatment is used avoiding thermal overheating. The long lifespan of the products contributes to the eco-friendliness of the choice of stainless steel that guarantees because of its mechanical resistance an extreme durability. Not only is steel 100% recyclable, but also almost eternal.

From concept to finished product, every single step involved in CEA production is traced and managed to guarantee process times and optimisation. The production flow follows procedures put in place for the reduction of waste, workplace ergonomics, vertical warehouses and automated picking, according to the canons of LEAN PRODUCTION. Industrialisation 4.0 goes hand in hand with sustainability of the production site and process. The building,

the company’s headquarters, develops vertically and favours

levels below ground to reduce occupation of land planted with vegetation and lower impact on the surrounding environment. The underground production divisions exploit the natural insulation ensured by the ground for cooling and heating of their interiors. The energy used by this department is provided exclusively by renewable sources, while the testing units are powered by a closed- circuit system to safeguard water resources. Vegetation and natural overhead light in the production areas further enhance the quality of the operators’ tasks and time spent at work. The result of this process is a product that is in turn sustainable, made with a noble, totally recyclable material that is highly hygienic, resistant to external agents, and long-lasting: stainless steel

CERTIFICATIONS AND SUSTAINABILITY

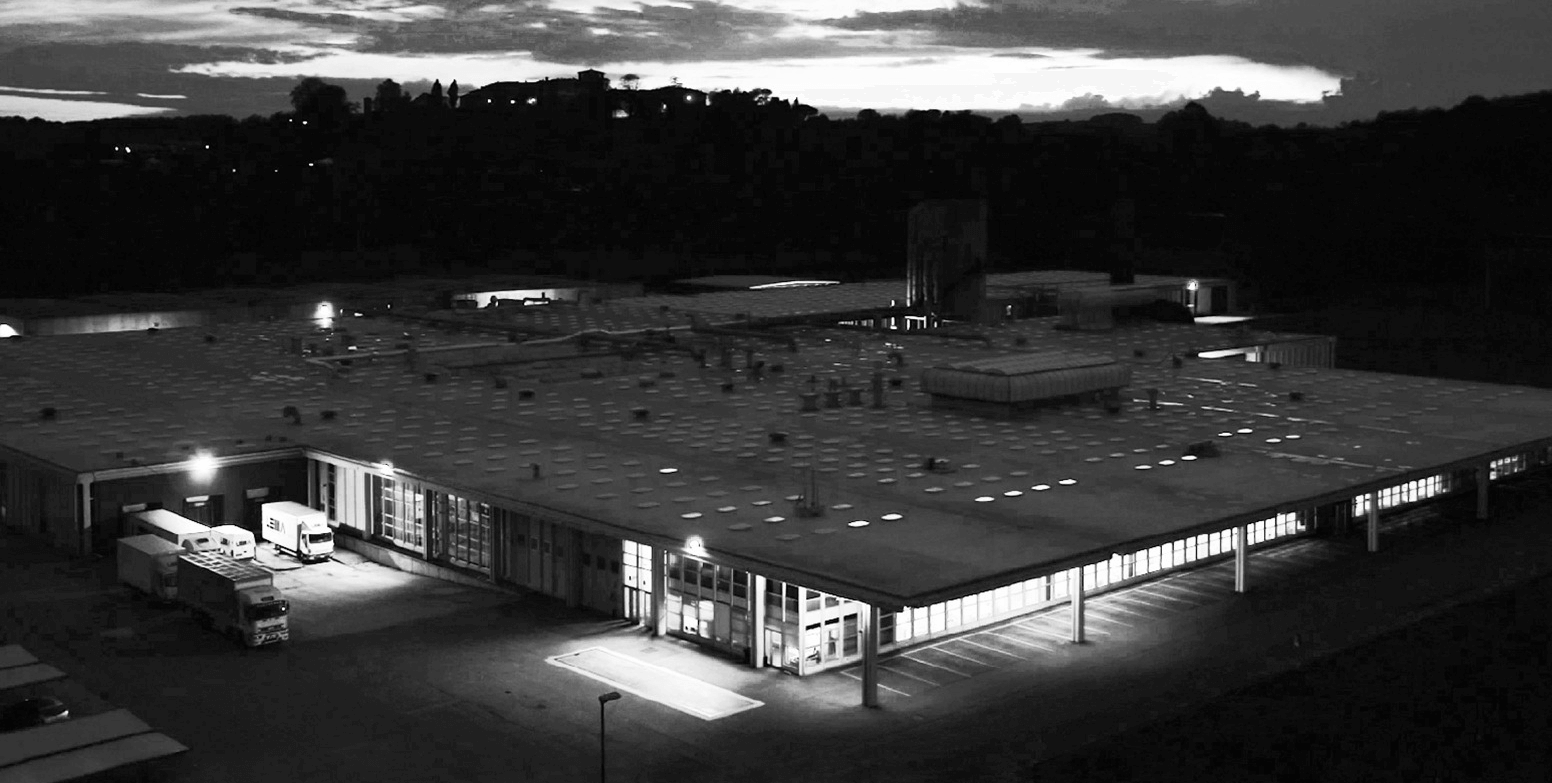

Lema has always had a keen focus on environmental issues and is constantly striving to improve its operation, adhering to regulations which favour the use of sustainable processes and materials. Key steps taken over the years include the progressive move from traditional to water-based paints, as well as a concerted effort to limit emissions. Our headquarters in Alzate runs partially on renewable energy, while the entire logistics area opened in 2013 is completely self-sufficient in terms of energy thanks to the photovoltaic plant installed on the roof. The company has had BS OHSAS 18001 certification since 2012, in recognition of our commitment to improving the working conditions at our facilities and in 2020 it obtained the international certification UNI ISO 45001, which attests the company’s responsibility towards protecting the health and safety of its employees. By request, Lema is also able to produce products with international FSC® certification, which denotes products containing wood sourced from forests that are sustainably managed in accordance with stringent environmental, social and economic standards. FSC® is an independent, non-profit international NGO whose members include environmentalist and social groups, indigenous communities, forest owners, industries who work with or sell wood and scientists and technicians who work together to improve forestry management across the world. In 2013, Lema also acquired ISO 9001 certification, the world’s leading Quality management standard. ISO 9001 certification shows that the company is active in programmes that aim to ensure the constant improvement of company performance and allow it to assure clients that it will maintain and improve the quality of its products and services.

FURNITURE AND MATERIALS THAT RESPECT THE ENVIRONMENT

Zalf eco panels uses wood particles, taken from the re-use of woody material, the logic of respect for nature

and the final consumer.

Zalf years designing and producing the knowledge and the goal

of preserving the great “home ground”. Over the years, so has recognized the importance of sustainable design and cross products and production systems business. The ecopanels with very low emission of formaldehyde, is compliance with the “CARB Phase 2” which lowers drastically, by today’s standards, the maximum permitted levels of formaldehyde emission. The structures of the furniture is coated with melamine paper abrasion-resistant and easy to clean.

ZERO EMISSIONS AND 100% RECYCLABILITY OF THE PACKAGING

Zalf has revolutionized the heating system of its facilities, replacing the “old” and traditional boilers with the latest biomass combustors that eliminate all the fumes due to impurities. The biomass also, does not contribute to the greenhouse effect. All packaging Zalf (polystyrene, cardboard and shrink wrap) are 100% recyclable.

PARTICULAR ATTENTION TO THE NATURE AND HOUSEHOLDS

Zalf is very attentive to households, by proposing and suggests a diverse range of lighting systems with LED light source, which compared to common fluorescent lamps offer energy savings up to 80% more than they will last at least 10 times , do not produce ultraviolet rays and generate very little heat. All packaging Zalf (polystyrene, cardboard and shrink wrap) are 100% recyclable.